Trailers are essential for transporting goods, vehicles, and even homes. The backbone of any trailer is its axle. Choosing the right trailer axle is crucial for safety, efficiency, and overall performance. In this guide, we’ll explore everything you need to know about trailer axles, from types and functions to maintenance tips and installation.

Table of Contents

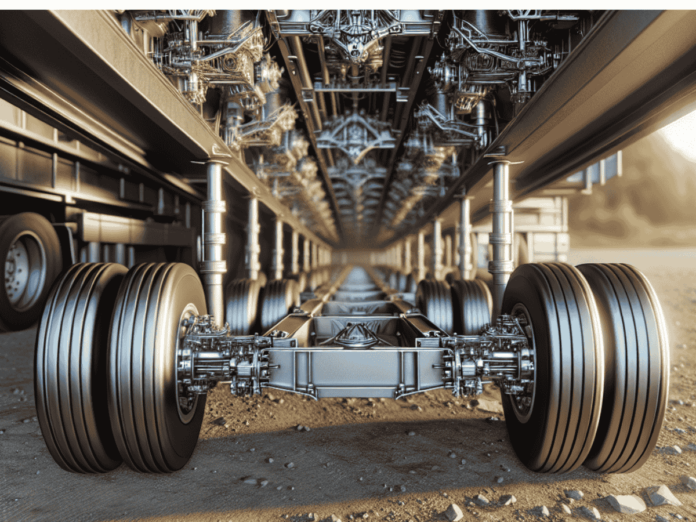

Understanding the Basics of Trailer Axles

A trailer axle is a crucial component that supports the weight of the trailer and its load. It connects the wheels and allows them to rotate while keeping the trailer stable. The right axle ensures that your trailer rolls smoothly, handles well, and remains safe on the road.

Types of Trailer Axles

There are several types of trailer axle, each suited for different applications. The most common types include leaf spring axles, torsion axles, and drop axles. Leaf spring axles are widely used due to their durability and ability to handle heavy loads. Torsion axles provide a smoother ride because they use rubber cords for suspension. Drop axles lower the trailer’s height, making it easier to load and unload.

Single vs. Tandem Axles

When choosing a trailer axle, you’ll need to decide between single and tandem axles. Single axles are ideal for lighter loads and shorter trips. They are easier to maneuver and require less maintenance. Tandem axles, on the other hand, offer better stability and weight distribution, making them suitable for heavier loads and longer distances.

Key Components of a Trailer Axle

Understanding the components of a trailer axle can help you make an informed decision. The main parts include the axle beam, spindles, hubs, and bearings. The axle beam is the central shaft that connects the wheels. Spindles are the tapered ends of the axle beam that attach to the wheels. Hubs house the wheel bearings and allow the wheels to rotate. Bearings reduce friction and support the weight of the trailer.

Selecting the Right Trailer Axle Kit

Choosing the right trailer axle kit is essential for ensuring a smooth and safe ride. A trailer axle kit typically includes the axle beam, hubs, bearings, seals, and mounting hardware. Here are some factors to consider when selecting an axle kit.

Load Capacity

The load capacity of the axle is one of the most critical factors to consider. It determines how much weight the axle can safely support. Ensure that the axle’s load capacity matches or exceeds the weight of your trailer and its cargo.

Axle Placement

Proper axle placement is crucial for maintaining balance and stability. The axle should be positioned to evenly distribute the weight of the load. Incorrect placement can lead to poor handling and increased wear on tires and suspension components.

Hub and Bearing Compatibility

Ensure that the hubs and bearings included in the axle kit are compatible with the wheels on your trailer. Mismatched components can lead to premature wear and potential failure. Check the specifications provided by the manufacturer to ensure a proper fit.

Installing a Trailer Axle

Installing a trailer axle requires precision and attention to detail. Proper installation ensures that your trailer operates safely and efficiently. Here’s a step-by-step guide to help you through the process.

Preparation and Tools

Before you begin, gather all necessary tools and materials. You’ll need wrenches, jacks, jack stands, a torque wrench, and the axle kit. Make sure you have a clean and level workspace to perform the installation.

Removing the Old Axle

If you’re replacing an existing axle, start by safely lifting the trailer using jacks and supporting it with jack stands. Remove the wheels and disconnect any brake lines or wiring attached to the axle. Unbolt the old axle from the trailer frame and carefully lower it to the ground.

Installing the New Axle

Position the new axle under the trailer and align it with the mounting points on the frame. Secure it in place using the provided hardware, ensuring all bolts are tightened to the manufacturer’s specifications. Reconnect any brake lines or wiring, then reinstall the wheels. Lower the trailer and check for proper alignment and operation.

Maintaining Your Trailer Axle

Regular maintenance is essential for keeping your trailer axle in top condition. Proper care can extend the life of the axle and ensure safe operation.

Inspecting for Wear and Damage

Regularly inspect the axle for signs of wear, damage, or corrosion. Check for cracks, bends, or other deformities in the axle beam and spindles. Look for signs of excessive wear on the hubs and bearings.

Lubrication and Greasing

Proper lubrication is essential for reducing friction and preventing premature wear. Regularly grease the bearings and other moving parts according to the manufacturer’s recommendations. Use high-quality grease designed for trailer axles to ensure optimal performance.

Checking Alignment and Balance

Maintaining proper alignment and balance is crucial for safe operation. Periodically check the alignment of the axle and adjust it if necessary. Ensure that the load is evenly distributed to prevent uneven wear on tires and suspension components.

Upgrading Your Trailer Axle

Upgrading your trailer axle can enhance performance and extend the life of your trailer. Here are some reasons to consider an upgrade.

Improved Load Capacity

If you frequently haul heavy loads, upgrading to a higher-capacity axle can improve safety and performance. A stronger axle can better support the weight and reduce strain on other components.

Enhanced Suspension

Upgrading to a torsion axle can provide a smoother ride and reduce wear on tires and suspension components. Torsion axles offer better shock absorption and stability compared to leaf spring axles.

Increased Durability

Choosing a high-quality axle with robust construction can extend the life of your trailer. Look for axles made from durable materials and designed to withstand harsh conditions.

Common Issues with Trailer Axles

Understanding common issues with axles can help you address problems before they become serious. Here are some typical problems and their solutions.

Bearing Failure

Bearing failure is a common issue with trailer axle kit. It can result from improper lubrication, overloading, or contamination. Regularly inspect and grease the bearings to prevent failure. If you notice unusual noises or excessive heat, replace the bearings immediately.

Bent or Damaged Axle

A bent or damaged axle can compromise the safety and performance of your trailer. It can result from overloading, impact, or corrosion. If you suspect a bent axle, have it inspected by a professional and replace it if necessary.

Tire Wear

Uneven tire wear can indicate alignment or balance issues with the axle. Regularly check the alignment and balance of the axle and adjust it if needed. Ensure that the load is evenly distributed to prevent excessive wear on one side.

When to Replace Your Trailer Axle

Knowing when to replace your trailer axle is essential for maintaining safety and performance. Here are some signs that it’s time for a replacement.

Excessive Wear and Tear

If you notice significant wear and tear on the axle components, it may be time for a replacement. Look for cracks, bends, or other deformities in the axle beam and spindles.

Frequent Repairs

If you find yourself frequently repairing the axle or related components, consider replacing it. Frequent repairs can indicate underlying issues that may not be fixable.

Upgrading for Better Performance

If you’re looking to improve the performance of your trailer, upgrading to a new axle can be a worthwhile investment. A higher-capacity or more advanced axle can enhance safety and efficiency.

Choosing the Best Trailer Axle Brands

Selecting a reputable brand can ensure that you get a high-quality axle that meets your needs. Here are some top brands known for their reliability and performance.

Dexter Axle

Dexter Axle is a well-known manufacturer of high-quality trailer axles. They offer a wide range of axles for various applications, including leaf spring, torsion, and drop axles. Dexter is known for their durability and excellent customer support.

AL-KO

AL-KO provides innovative with advanced features. Their axles are designed for enhanced performance and durability. AL-KO offers both leaf spring and torsion axles to suit different needs.

Lippert Components

Lippert Components is a leading supplier of trailer for axles and related components. They offer a variety of axles known for their strength and reliability. Lippert axles are used in a wide range of applications, from recreational trailers to heavy-duty commercial trailers.

My suggestion for your garage? Check out our article Best Car Lift for Home Garage: Elevate Your Garage Experience to discover top car lift options that bring professional-grade convenience to your home setup.

Enhancing Safety with Trailer Axle Accessories

Using the right accessories can enhance the safety and performance of your trailer. Here are some essential accessories to consider.

Brake Systems

Brake systems are crucial for safely stopping your trailer. Electric brakes and hydraulic brakes are common options. Ensure that your axle is compatible with the brake system you choose.

Suspension Kits

Suspension kits can improve the ride quality and handling of your trailer. They help absorb shocks and reduce wear on tires and suspension components. Look for kits designed for your specific axle type.

Tire and Wheel Upgrades

Upgrading your tires and wheels can enhance the performance and durability of your trailer. Choose high-quality tires designed for your load capacity and intended use. Ensure that the wheels are compatible with your axle hubs.

Conclusion

Choosing the right trailer axle is essential for the safety, performance, and longevity of your trailer. By understanding the different types of axles, selecting the right components, and maintaining them properly, you can ensure a smooth and reliable ride. Whether you’re hauling light loads or heavy cargo, investing in a high-quality axle can make all the difference. If you’re ready to upgrade or replace your trailer axle, explore our selection of top-rated axles and accessories.

Frequently Asked Questions About Trailer Axle:

What are the signs of a failing trailer axle?

Common signs of a failing trailer axle include unusual noises, excessive tire wear, misalignment, and issues with the suspension. If you notice any of these symptoms, it’s crucial to inspect the axle and components thoroughly to assess the extent of the problem.

How often should trailer axles be serviced?

Trailer axles should be serviced regularly, at least once a year or every 12,000 miles, whichever comes first. Regular maintenance including checking and greasing bearings, inspecting for damage, and ensuring proper alignment can help prolong the life of your axle.

Can I upgrade my trailer axle myself?

While some skilled individuals may be able to upgrade a trailer axle themselves, it is often recommended to have a professional perform the upgrade. Installing a new axle requires precise alignment and mounting to ensure safety and optimal performance.

What’s the difference between leaf spring and torsion axles?

Leaf spring axles use a system of metal springs to absorb shock and provide a stable ride, while torsion axles use rubber cords inside the axle beam. Torsion axles generally provide a smoother ride and require less maintenance, but they may be more costly than leaf spring options.

How do I choose the right axle for my trailer?

To choose the right axle for your trailer, consider your trailer’s load capacity, the terrain you’ll be traveling on, and your specific performance needs. It’s important to select an axle that can handle the weight and provide reliable performance over time. Reviewing manufacturer recommendations and consulting with professionals can help guide your decision.